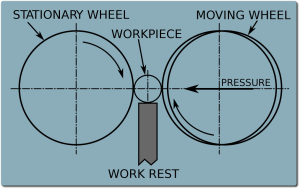

Centerless Grinding

Centerless grinding consists of removing material from a cylindrical workpieces with the use of two rotating wheels, one of which (or both) being a grinding wheel. While the wheels are in rotation, the workpieces are inserted on a work rest, between the wheels, which grind away material while the workpieces travel between the two wheels, exiting on the other side of the wheels.

Click image to enlarge

Centerless grinding is typically preferred over more conventional grinding methods for operations where many parts must be processed.

Some of the advantages of centerless grinding are:

- Grinding in very hard materials

- Ability to produce very smooth and precise surfaces, which in turn allows for higher mechanical quality and performance

- Ability to attain tolerances in the tenths of thousands of an inch (i.e. 0.0004″)

Click image to enlarge